Enterprise hotline:020-86064436| After-sales hotline:020-26269545

-

Solution

Rattop audio and video digital products are widely used in education, government, enterprises and institutions, emergency management, smart cities, rail transit, telecommunications, power, manufacturing and many other fields!

View More >Education industry Medical place Transportation Industry Government and enterprise units Service Industry Cultural tourism Manufacturing industry Sports venues Judiciary More Programs Campus Report Hall Conference System Construction Scheme

Campus Report Hall Conference System Construction SchemeThe multimedia lecture hall mainly realizes various functions such as various large, medium and small international conferences, ordinary conferences, entertainment performances, multimedia screenings, reports, training, lectures, synchronous recording of conferences, intelligent centralized control, etc.

Campus Broadcasting System Construction Scheme

Campus Broadcasting System Construction SchemeThe digital IP network broadcasting system adopts the TCP/IP network technology widely used in the world today, and transmits the audio signal in the form of data packets on the local area network and wide area network.

Campus Conference Room Conference System Construction Scheme

Campus Conference Room Conference System Construction SchemeThe school conference room is generally used for academic reports, small and medium-sized meetings, video conferences, training, organizing school activities and receiving visitors.

Construction scheme of professional sound reinforcement system in campus gymnasium

Construction scheme of professional sound reinforcement system in campus gymnasiumThe school gymnasium is mainly used to host school basketball, volleyball, table tennis, badminton and other competitive sports competitions, and is also used for multi-functional use such as assemblies and large-scale cultural and entertainment activities.

Hospital Report Hall Conference System Solution

Hospital Report Hall Conference System SolutionThe multimedia lecture hall mainly realizes various large, medium and small international conferences, ordinary conferences, entertainment performances and multimedia screenings.

Meeting System Solution of Hospital Meeting Room

Meeting System Solution of Hospital Meeting RoomThe use of the hospital conference room is very extensive, generally held for various meetings within the hospital, academic exchange meetings, patient reception and consultation

Solution of Public Broadcasting System in Hospital Park

Solution of Public Broadcasting System in Hospital ParkThe digital IP network broadcasting system uses TCP/IP network technology, which is widely used in the world today, to send audio signals in the form of data packets.

Solution of Station Public Address System

Solution of Station Public Address SystemThe digital IP network broadcasting system adopts the TCP/IP network technology widely used in the world today, and the audio signal is in the form of data packets in the local area network.

High-speed public address system solutions

High-speed public address system solutionsHighway broadcasting system plays a very important role in traffic operation, passenger service, disaster prevention and rescue, equipment maintenance and so on. When the subway passenger flow surges caused by major events and festivals, as an important means of implementing emergency passenger transport organization, it provides guarantee for the operation organization of large passenger flow.

Solution of High-speed Visual Intercom Broadcasting System

Solution of High-speed Visual Intercom Broadcasting SystemThe visual network broadcasting intercom system integrates the network digital audio transmission system and the network intercom system. The main equipment in the system can be used as broadcasting equipment or intercom equipment. The two systems are compatible with each other to realize centralized management and unified control.

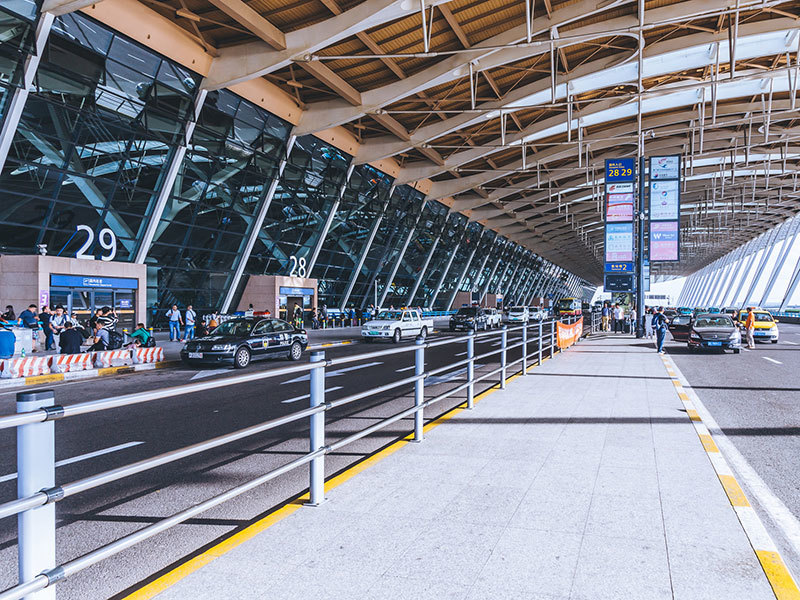

Airport Public Address System Solution

Airport Public Address System SolutionThe digital IP network broadcasting system adopts the TCP/IP network technology widely used in the world today, and transmits the audio signal in the form of data packets on the local area network and wide area network, which completely solves the problems of poor sound quality, complex maintenance and management, and poor interactive performance of the traditional broadcasting system.

Airport Meeting Room Multimedia Conference System

Airport Meeting Room Multimedia Conference SystemAirport meeting rooms are generally used for various business meetings, training and education, volunteer and volunteer organizations, and temporary office purposes. The airport meeting room provides a convenient and professional place to meet the needs of different organizations and people.

Government and Enterprise Unit Building Broadcasting System Solution

Government and Enterprise Unit Building Broadcasting System SolutionGovernment and enterprise units play an important role in serving the society, creating culture, providing employment opportunities, providing high-quality products and services to consumers and feeding back the society.

Solution of Conference Sound Acoustic System in Conference Room of Government and Enterprise Units

Solution of Conference Sound Acoustic System in Conference Room of Government and Enterprise UnitsThe conference room of government and enterprise units is an important workplace and communication platform, which is widely used and diversified. The equipment selection of meeting room audio sound reinforcement system should be based on the functional requirements of the meeting place.

Multimedia Conference System Solution for Government and Enterprise Conference Room

Multimedia Conference System Solution for Government and Enterprise Conference RoomAs an important place for enterprises, governments and other important units, leaders and employees discuss and solve work problems together. The requirements for conference rooms are getting higher and higher. Various intelligent systems are needed to ensure the stability, safety, convenience and efficiency of the meeting agenda.

Restaurant Public Address System Solution

Restaurant Public Address System SolutionThe application of public address system in restaurants is constantly integrating into the needs and trends of the times. This application is not just to provide background music, but through a variety of ways to enhance the dining experience, convey information and create a distinctive atmosphere.

Hotel Ballroom Conference Sound System Solution

Hotel Ballroom Conference Sound System SolutionThe selection of audio sound reinforcement system equipment in the banquet hall should be based on the functional requirements of the meeting place and combined with the actual building layout conditions. The principle of system configuration should follow the principles of applying new technology, reasonable system configuration, stable and reliable system operation and convenient operation.

Hotel Smart Cloud Broadcasting System Solution

Hotel Smart Cloud Broadcasting System SolutionThe hotel's broadcasting system is mainly to cover up the noisy noise, to provide guests with a leisurely and fresh environment, to ease the mood of the guests, as well as broadcast notification, search for people and other public broadcasting functions.

Shopping Mall Public Address System Solution

Shopping Mall Public Address System SolutionIn recent years, with the continuous development of the economy, China's residents consumption level continues to improve, shopping demand has also been rapid development, shopping malls are a collection of food, entertainment, leisure and a variety of business activities in one of the public places

Solution of Community Smart Cloud Broadcasting System

Solution of Community Smart Cloud Broadcasting SystemAs one of the most important information dissemination tools to create a harmonious environment in residential quarters, the public broadcasting system has become an indispensable system for the normal operation of many residential quarters, which is inseparable from the intelligent weak current system in residential quarters.

Solution of Public Broadcasting System in Museum Library

Solution of Public Broadcasting System in Museum LibraryIn museums and libraries, the application of public address systems is becoming more and more important. As public cultural institutions, museums and libraries bear the important responsibility of publicizing cultural knowledge, educating the public and providing information services.

Solution of Public Broadcasting System in Park Scenic Area

Solution of Public Broadcasting System in Park Scenic AreaIn recent years, the warming of tourism has accelerated the informatization construction of parks and scenic spots. Especially in terms of tourist safety and scenic spot management, tourism units have adopted new technologies and new products to carry out substantial transformation and construction to meet the needs of the expanding tourism market.

Theatre Concert Hall Conference Sound System Solution

Theatre Concert Hall Conference Sound System SolutionDriven by the background of the times, the theater music multimedia conference sound reinforcement system integrates advanced audio and video processing technology, wireless technology and interactive functions to achieve high-quality, flexible and convenient music performance and conference experience.

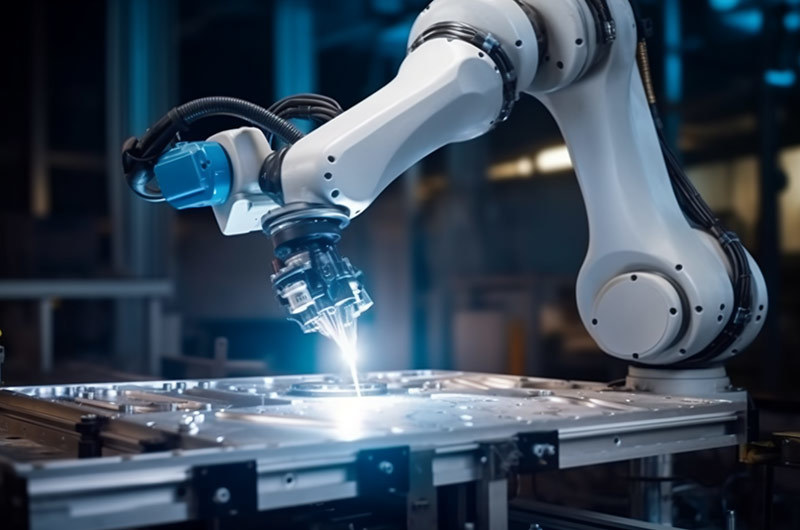

Factory Meeting Room Multimedia Conference System Solution

Factory Meeting Room Multimedia Conference System SolutionAs an important meeting place for government and enterprises, multimedia conference rooms are used by leaders and employees to discuss and solve work problems. The requirements for conference rooms are getting higher and higher. It is necessary to match various intelligent systems to ensure the stability, safety, convenience and efficiency of the meeting agenda.

Factory Visual Intercom Broadcasting System Solution

Factory Visual Intercom Broadcasting System SolutionThe IP network visual broadcast intercom system integrates the IP network digital broadcast system with the IP network intercom system. The main equipment in the system can be used as broadcast equipment or as intercom equipment. The two systems are compatible with each other to realize centralized management and unified control.

Solution of Factory Digital IP Network Broadcasting System

Solution of Factory Digital IP Network Broadcasting SystemIn order to strengthen the management of the factory area and create a comfortable and relaxed working environment, many modern enterprise factories have the need to build and transform an IP network broadcasting system, including factory fire safety.

Solution of Digital IP Network Broadcasting System for Stadium

Solution of Digital IP Network Broadcasting System for StadiumA gymnasium is a venue for sports competitions, performances and other large-scale events. In order to provide a good viewing and listening experience, digital IP network broadcasting system is widely used in the stadium.

Gymnasium conference sound reinforcement system solution

Gymnasium conference sound reinforcement system solutionWith the continuous progress of technology, the technology of conference sound reinforcement system is also constantly innovating and developing. The new generation of sound reinforcement system can realize digital audio transmission, networked operation and intelligent control, and provide more high-quality and convenient audio experience for sports venues.

Judicial organ report hall meeting system solution

Judicial organ report hall meeting system solutionThe construction of the multimedia conference system in the report hall of the judicial organ is closely related to the development of the times and the actual needs. It can meet the informatization needs of the judicial organ, the needs of cross-regional cooperation, and the needs of real-time and effective communication.

Judiciary Multimedia Conference Room

Judiciary Multimedia Conference RoomAs an important place for judicial organs and other important places, leaders and employees discuss and solve work problems together. The requirements for the conference room are getting higher and higher, and various intelligent systems are needed to ensure the stability of the meeting agenda.

Solution of Sound Acoustic System for Meeting Room of Judicial Organs

Solution of Sound Acoustic System for Meeting Room of Judicial OrgansThe application of the conference sound reinforcement system in the conference room of the judicial organ can improve the sound transmission effect, improve the communication efficiency of the participants, and provide flexible volume and sound control.

Command Center Conference System Solution

Command Center Conference System SolutionThe command center is a place for consultation and command during the handling of public incidents. It has the function of holding a video conference, which is convenient for leaders to listen to the situation report and expert consultation suggestions, and conduct remote command. With image access function

Distributed Audio and Video Management System Solution

Distributed Audio and Video Management System SolutionThe distributed audio and video integrated management system is dominated by command technology and information technology, making full use of modern communication technology, network technology, automation technology, electronic monitoring and other advanced technologies, building a data transmission network as a link, supported by computer information systems.

Conference Speech System Solution

Conference Speech System SolutionThe conference presentation system includes a traditional conference system, a wired digital conference system, a wireless conference system, and a 5G WIFI conference system, which provides participants with functions such as discussion, voting, sign-in, camera tracking, and simultaneous interpretation during the conference.

Conference sound reinforcement system solution

Conference sound reinforcement system solutionThe conference sound reinforcement system includes sound reinforcement equipment and sound field components, mainly including sound sources and its surrounding sound environment, the sound into electrical signals of the microphone, signal amplification and signal processing equipment, transmission lines, the signal into acoustic signals of the speaker and the acoustic environment of the audience area.

System Solution of Conference Recording and Broadcasting System

System Solution of Conference Recording and Broadcasting SystemThe conference recording and broadcasting system mainly uses the recording and broadcasting host with various audio and video equipment to realize real-time recording of various materials such as the speeches of the conference personnel and the conference process in the conference. It can also allow people outside the conference hall to remotely access the recording and broadcasting host through mobile phones or computers through web pages to watch in real time and participate in the conference remotely, thus meeting the use needs of many enterprises.

Conference all-in-one system solution

Conference all-in-one system solutionThe conference all-in-one system has the functions of writing, annotation, video conference, one-button screen projection, document management, etc. It integrates curtain, projector, electronic whiteboard, monitor, computer, advertising machine and audio, and can easily realize various conference scenes, product display and publicity, etc.

Meeting Reservation System Solution

Meeting Reservation System SolutionThe conference reservation system is an intelligent management system that integrates reservation management and sign-in recognition. Conference organizers can make reservations through the software platform, conference terminal equipment and WeChat public number, and can find free conference rooms that meet the requirements at a glance through real-time conference monitoring information.

-

Products

Rattop's public broadcasting system includes smart cloud platform broadcasting, village-to-village broadcasting, highway broadcasting, visual docking broadcasting, etc......

View More >Public address system Conference System Lighting system Conference management system Distributed audio and video management system Smart Cloud Platform Digital Network Broadcasting System

Smart Cloud Platform Digital Network Broadcasting SystemThe intelligent cloud platform IP network broadcasting system is based on the mobile Internet and the Internet of Things environment. It adopts cloud computing, big data processing technology and distributed server architecture "cloud platform system". It controls the front end and terminals to access through the Internet or mobile Internet. It provides real-time and reliable audio broadcasting, paging and shouting, cross-regional, multi-platform management and other functions for large-scale broadcasting terminals.

Visual intercom system

Visual intercom systemIn order to cooperate with the "Thirteenth Five-Year Development Plan for Transportation Informatization" and adapt to the informatization development of the expressway industry, the integrated communication command technology is applied to the daily management of the expressway, and the intelligent operation of the expressway is realized. Highway visual intercom command and dispatch system solution. Through the integration of intercom with highway toll booth, emergency help, emergency broadcast, monitoring and office communication systems, it helps the high-speed industry to maximize management efficiency and economic benefits.

All-digital two-way IP network broadcasting system

All-digital two-way IP network broadcasting systemThe digital two-way IP network broadcasting system is based on the Internet protocol, which uses network technology to convert analog audio signals into digital signals and transmit them in the local area network. It breaks through the content limitation, space limitation and function limitation of the traditional analog broadcasting system. Diversified broadcasting function design has diversified broadcasting functions such as timing broadcasting, live broadcast on demand, multi-area audio distribution, high concurrency, low delay, constant pressure backup mode, etc. The system is based on the existing computer network construction and does not need to be wired separately, it realizes the all-digital network broadcasting system of audio broadcasting, video monitoring and computer network.

Every Village "Big Horn"

Every Village "Big Horn"In order to improve the level of public cultural services and help rural revitalization and the construction of a new socialist countryside for digital rural construction, Rattop Technology has joined hands with China Mobile

5G "cloud" platform broadcast system

5G "cloud" platform broadcast systemThe 5G cloud platform broadcasting system refers to the 4G and 5G networks with super coverage as pipelines and intelligent sound columns, intelligent receiver, cloud microphones and other equipment as broadcasting carriers to provide intelligent supervision methods for various management departments and timely transmit information such as policies and regulations, party building knowledge, weather forecast, garbage classification, epidemic prevention knowledge, emergency measures, etc.

Analog broadcasting system

Analog broadcasting systemAnalog broadcasting system uses analog technology, the sound quality is slightly inferior to that of digital broadcasting system, but the price is cheaper than that of digital broadcasting system. The main characteristics of analog broadcasting system are low price, easy maintenance and wide application range.

Teaching sound reinforcement system

Teaching sound reinforcement systemAn instructional sound reinforcement system is an educational sound system specifically designed to provide balanced, clear sound amplification in places such as classrooms or conference rooms. characteristics. It needs to be matched with microphones, speakers and other equipment. After the construction is completed, it will help improve the sound quality and volume of multimedia teaching, and realize the function of easy and free speech and teaching.

Meeting Hand-in-Hand System

Meeting Hand-in-Hand SystemHand-in-hand conference system is a specially designed conference system, its biggest feature is the use of microphone end-to-end series connection. This system ensures that everyone has an equal opportunity to participate in the discussion and that there is no confusion when speaking at the same time.

Digital Hand-in-Hand System

Digital Hand-in-Hand SystemWith the advent of the mobile Internet era and the development of touch technology and WIFI Internet, Rattop Technology has successfully launched a 5G/WIFI wireless conference system, which adopts standard 802.11n technology

Conference Microphone (Wired and Wireless)

Conference Microphone (Wired and Wireless)Conference microphone is one of the important equipment to ensure the smooth progress of the conference. It not only needs to have high-quality sound quality, but also needs to have the characteristics of ease of use, appearance design, anti-howling function and easy maintenance to meet the actual needs of the conference scene.

Surrounding the conference

Surrounding the conferenceThe conference system peripheral equipment refers to the auxiliary equipment related to the conference system. These equipment can enhance the function and performance of the conference system, and improve the efficiency and comfort of the conference.

Professional sound reinforcement system

Professional sound reinforcement systemProfessional conference sound reinforcement system is suitable for conference sound reinforcement, multimedia activities, theatrical performances and other uses of comprehensive information resources exchange places.....

Stage Lighting

Stage LightingAccording to the development of the plot, the characters and specific scenes are rendered visually, and the design intention is reproduced to the audience as a visual image. The stage lighting system of Rattop Technology ...

Lighting intelligent control

Lighting intelligent controlIntelligent lighting control system can be widely used in homes, offices, hotels, shopping malls and other places to improve the comfort and efficiency of life and work.

Smart paperless office system

Smart paperless office systemIn order to comply with the development of information technology application innovation industry, maintain data security and network security, realize independent control in the field of information technology, and ensure...

Conference Reservation System

Conference Reservation SystemThe meeting reservation system is a kind of meeting schedule which can help the organizer to create, manage and query the meeting schedule easily, and ensure that the meeting facilities are reasonably allocated and used.

Electronic table board system

Electronic table board systemElectronic table board system is a kind of information that can display the names, positions, departments and other information of participants through electronic screens or mobile devices, so that participants can more easily understand the situation of participants in the meeting.

Meeting tablet all-in-one machine

Meeting tablet all-in-one machineThe conference tablet all-in-one machine integrates computer, monitor, audio and other functions, and can easily realize various conference scenes, product display and publicity, etc.

Distributed system

Distributed systemFocusing on the new ecology of the development of the digital economy industry, Rattop Technology's distributed audio and video management system came into being, providing a new concept of management and control platform...

Central Control/Matrix

Central Control/MatrixWith the continuous updating and reform of social information technology, various audio-visual facilities, Internet of things products, multimedia equipment into the daily. Traditional operations are becoming more and more...

-

Case

Rattop Technology is deeply involved in the real economy, and audio and video digital products are widely used in education, government, enterprises and institutions, emergency ......

View More >Education industry Medical place Transportation Industry Government and enterprise units Service Industry Cultural tourism Manufacturing industry Sports venues Judiciary More cases Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities Beijing

Beijing Shanghai

Shanghai Tianjin

Tianjin Anhui

Anhui Fujian

Fujian Gansu

Gansu Guangdong

Guangdong Guangxi

Guangxi Shandong

Shandong Hainan

Hainan Hebei

Hebei Henan

Henan Heilongjiang

Heilongjiang More Cities

More Cities -

Service

Focusing on the digital economy industry, and actively complying with the development trend of networked, intelligent, and digital management of the audio and video industry, Rattop ......

View More > -

About Us

Rattop (Guangdong) Technology Co., Ltd. focuses on the digital economy industry. It is a national high-tech enterprise based on the Internet of Things platform with audio as the core......

View More >

Manufacturer of integrated audio and video solutions

News

Fault Inspection Method of Public Address System

After the initial debugging or operation of the broadcasting system fails, we usually find the faulty equipment according to the program signal process and carry out simple maintenance. If the equipment failure is more complex, or the manufacturer warranty and does not allow the user to repair, it should be directly returned to the manufacturer for repair. The following is a simple method of maintenance.

1. Visual inspection method

Visual inspection method is immediately after the power is disconnected. Do not use instruments, meters, with intuitive feeling, to mobilize the visual, auditory, olfactory, tactile and other senses, to judge. Although this inspection method is less accurate, it is fast, and the visual inspection method is especially useful for power failure inspection.

Look: Observe the machine or component and its external structure. Check whether the key switch, interface and indicator light are loose, whether the connecting thread of the circuit board falls off, whether there is virtual welding, discoloration, crack, burst and other phenomena, whether the fuse is blown, lit, smoke, deformed, not stuck and other problems, and use eyes to directly identify and judge.

Second listening: gently turn the machine or parts, swing, listen to whether there are parts scattered or screws falling off, whether there is a collision sound. Do continuous turnover to see if there is any abnormal "squeaking" sound or "popping" sound (when power is on). If there are these phenomena, the fault may appear in these places.

Three sniffing: use your nose to smell if there is a burning smell, find the source of the smell, the fault may be a place that emits peculiar smell.

Four touch: touch the transformer shell by hand (after power failure), do not touch the terminal, because sometimes due to the existence of charging capacitor, the voltage is very high, endangering safety. Feel whether it exceeds the normal temperature, is hot and cannot be touched. Whether the power tube is overheated or cold. Adjust whether the tube is overheated or cold. If there are these phenomena, the problem may appear in these places.

2. Tentative method

The test method is to use comparison, segmentation, substitution, simulation and other test methods for the suspected part of the circuit to find the fault and then eliminate it. Specific methods are as follows:

Comparison: Find a machine of exactly the same type as the fault machine, measure the voltage, resistance and current of the corresponding part, and then compare them to find the fault.

Segmentation: disconnect a certain part of the circuit from other parts, connect the external power supply, inject signals, and make judgments.

Substitution: Replace suspected components with good components, or swap left and right channel components, especially for integrated circuit blocks. If the machine returns to normal after a part swap, the part is defective or damaged.

Simulation: temperature simulation, the use of hair dryer heating, or alcohol cooling, temperature performance inspection, vibration simulation is the use of fine plastic insulation rod tap some parts, look at the circuit working conditions, you can find some virtual welding phenomenon, check the fault. This method is generally carried out by skilled technicians, otherwise, it is easy to aggravate the phenomenon of failure.

3. Static parameter measurement method

The measurement of static parameters shall hold the maintenance manual of the manufacturer's equipment, indicate the static working current or voltage of each component endpoint, and use a multimeter to measure the current, voltage or resistance value of each part of the circuit to see if it is consistent with the nominal value.

Resistance measurement: use the ohm gear × 100 or × 1K gear of the multimeter, and do not use the R× 10K gear, because the 22.5 volt battery is connected to the meter in this gear, which is inappropriate for transistor measurement and easy to damage the transistor. In the case of power failure, if there is a charging capacitor, it must be fully discharged with an insulated screw taper. One end of the resistance in the measurement circuit must be welded, otherwise the measurement is not accurate.

Voltage measurement: In the process of making this measurement, the influence of the internal resistance of the multimeter on the measured value should be considered. It should be noted that static measurements are not the same as dynamic measurements (when the signal is added). Measure whether the terminal voltage of each transistor pin, resistor and capacitor is consistent with the nominal value when static, and whether the tube is damaged can be judged by the relative voltage of the transistor pin.

Current measurement: when using direct measurement, string the ammeter into the circuit and check the current. When indirect measurement is used, the voltage at both ends is measured, and the voltage value is removed by the resistance value to obtain the current value.

In addition to static parameter measurement, but also the use of dynamic inspection method, the use of signal source and oscilloscope, direct inspection of the injection signal, the circuit to judge. This method is direct, accurate, and not easy to damage components, but also on the circuit and mechanical structure adjustment and proofreading.

Beijing Winter Olympics audio and video suppliers

Rattop Technology Service Number

Rattop Technology Subscription Number